assessing impact characteristics via tensile test data|weld metal tensile strength test : private label The uniaxial tensile test is the most commonly-used mechanical testing procedure. However, while it is simple in principle, there are several practical challenges, as well as a number of points to be noted when . WEB12 de nov. de 2020 · Cristina Ranzolin com o marido, Paulo Roberto Falcão, após o anúncio no Jornal do Almoço — Foto: Glaucius Oliveira/RBS TV . 2 de 2 Cristina Ranzolin — Foto: Reprodução/RBS TV .

{plog:ftitle_list}

Hentai Sem Censura. Ver tudo. Atualizado há 2 dias. Animes Hentai TV Assista hentai online HD grátis, são milhares de vídeos hentai sem censura e legendados! Baixar .

Tensile testing is used to determine the mechanical properties of a material, such as its tensile strength, yield strength, and elongation. In this blog post, we will focus on conducting tensile tests on copper wire, a widely-used material in various industries.

Impact Testing Impact testing ascertains the fracture characteristics of materials. It is used when laboratory tensile test results cannot be used to predict fracture behavior. One of the .

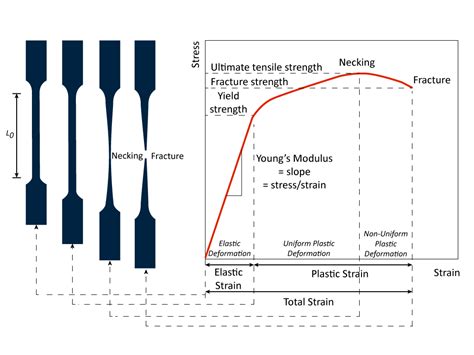

The results of the tensile test, often plotted on a stress-strain curve, provide key properties such as the material’s yield strength, ultimate tensile strength, modulus of elasticity, and elongation .TENSILE DATA ANALYSIS. The Tensile Example document presents a method to generate a stress-strain curve from test data. This visual representation helps to guide the determination . The uniaxial tensile test is the most commonly-used mechanical testing procedure. However, while it is simple in principle, there are several practical challenges, as well as a number of points to be noted when .Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test .

weld metal tensile strength test

Tensile test data have many uses. Tensile properties are used in selecting materials for various applications. Material specifications often include minimum tensile .

Uniaxial tensile tests are routinely conducted to obtain stress-strain data for forming applications. It is important to understand the deformation behavior of test specimens at plastic strains, . Tensile testing of materials is explained with reference to tensile testing equipment; and the stress-strain curves are analyzed to determine the various strength and .

Tensile Testing is a form of tension testing and is a destructive engineering and materials science test whereby controlled tension is applied to a sample until it fully fails. This is one of the most common mechanical testing techniques. It is . Exploring Elongation TestingElongation testing, a cornerstone of material science, reveals a material's ductility and strength when under tensile stress. By stretching a sample until it breaks, this test measures how much a material can deform before failing. In industries prioritizing safety and durability like automotive and construction, this insight is crucial. .

tensile strength test results

What is the Purpose of Tensile Testing? The tensile qualities of a material can be better understood with the help of a tensile test. These characteristics, such as the modulus of elasticity, strain, and yield strength, can be displayed graphically as a stress/strain curve, which can reveal information like the point at which the material broke.

Dissimilar aluminum joints have widespread applications across various industries, including the electronics and automotive sectors, owing to their unique combination of advantages, including reduced density and enhanced mechanical properties. These characteristics make them an innovative solution for multi-material processing challenges . What is the Charpy impact test used for? The purpose of the impact test is to assess the response of a known material, such as polymers, ceramics, and composites when subjected to sudden stress. It specifically evaluates the toughness, brittleness, notch sensitivity, and impact strength of engineering materials under high-rate loading. Quantifying the impact .This information is needed in virtually all mechanical products where strength and stiffness are design variables. Tensile test properties make it possible to select and compare materials, design components, ensure quality, and prevent product failures. Material Selection - Tensile test data enables comparison of different materials. a) Comparative stress-strain relationships of low carbon steel and aluminium alloy and b) the determination of the yield strength at 0.2% offset .3 Ultimate Tensile Strength, σ TS Beyond yielding .

tensile strength test pdf

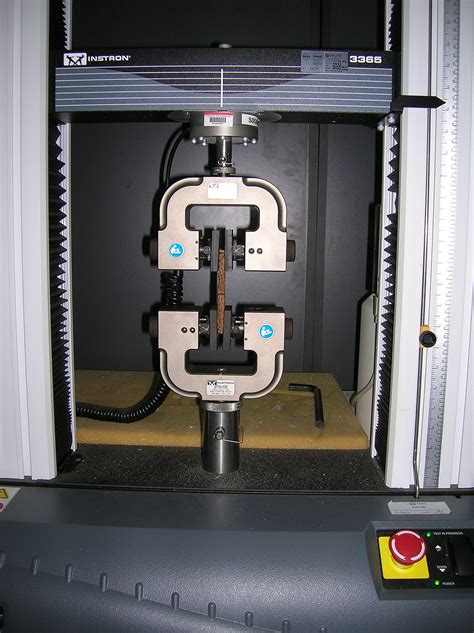

The tensile test is conducted by use of a tensile testing machine or universal testing machine; the latter can be used for both tension and compression tests. In tensile testing, the specimen is firmly held in place by grips of the testing machine (see Fig. 3.4). One end of the specimen is held firm, whilst the other end is pulled by applying a . Utilizing both compression and shear data with tension data as input in Mat-SAMP-1, it generates the SAMP-1 yield surface formulation for calculations. There are no fracture criteria and biaxial tension test date taken into account in any numerical simulations. The nonassociated flow rule in Mat-SAMP-1 is used in all simulations.

Tensile strengths of 2.0 to 5.0 mol% YâOâ-stabilized ZrOâ polycrystals are described using the newly developed tensile testing method. The tensile test was conducted by attaching three strain . Understanding the mechanical characteristics of rocks when subjected to direct tension is crucial for assessing the stability of rock formations. Within the scope of this research, a series of .

Both the load (stress) and the test piece extension (strain) are measured and from this data an engineering stress/strain curve is constructed, Fig.3.From this curve we can determine: a) the tensile strength, also known as the ultimate tensile strength, the load at failure divided by the original cross sectional area where the ultimate tensile strength (U.T.S.), σ max = P max /A 0, .

Many performance parameters can be measured by well executed tensile testing. The resulting data - a curve of force vs extension - shows the tensile profile of the test up to the point where the specimen breaks. . Quality assessment through tensile testing of interior fittings including: airbags, carpets, dashboards, electrical harness (incl .Filler metal manufacturers perform tensile testing on many of their products for several reasons. Like many end users, they may perform tensile testing to help monitor process quality. Tensile testing is also used by these manufacturers to determine and maintain product classifications and approvals from agencies such as the American Welding Society (AWS) or the American . Disc coal samples with different water content were tested using the split Hopkinson press bar test system. Their dynamic tensile failure process was monitored via an ultra-high-speed digital . Since the tensile test has a special significance in the assessment of base materials and in the examination of welded joints, the experimental conditions must be defined as precisely as possible, so that different testing .

There are a variety of different tensile testing characteristics that can be discovered and measured. Some of the more common measurements are listed below. . The results of a tensile test should provide helpful data to . The double criteria are generally obtained by means of a three-point flexural test and a single-crack tensile test 18,19. However, the double criterion can only be used to determine whether a . Immobilize the sample between two clamps (a commercial jig), one affixed to a 98.07 N load cell and the other to an immovable base plate 14.The resulting area between the clamps tested in uniaxial tension should be 1 cm x 4 cm (Figure 2).NOTE: A commercial jig was utilized to avoid non-uniform gripping and damage to the sample before testing. This research also shows that specific testing is required for new machine–material–infiltrate combinations to calibrate a performance model.,There is limited published data with respect to the strength characteristics that can be achieved using the 3DP process. No published data with respect to stress–strain curves are available.

Uniaxial test specimens were made of cold-rolled ASTM A1008 steel having a thickness of 2.94 mm. Tensile tests were conducted in a cruciform (biaxial) testing machine [6]. In this machine, the load is applied using hydraulic actuators, which are controlled in orthogonal pairs [6]. Each of these actuators has Ultimate Tensile Stress (UTS) and Ductility. It may be noted at this point that it is common during tensile testing to identify a “strength”, in the form of an “ultimate tensile stress” (UTS). This is usually taken to be the peak on the nominal stress v. nominal strain plot, which corresponds to the onset of necking.

In Materials Science and Engineering (MSE), material and process data are generated using a variety of different techniques. For instance, assessing a component’s degradation behavior at .

The small punch (SP) test has been widely used in applications where conventional mechanical tests cannot be performed; this paper predicts the material strength from the SP test results by empirical correlations method. The yield strength (YS) and ultimate tensile strength (UTS) models serve to associate the load–displacement (LD) curves of SP tests with .The tensile test is a test method within mechanical materials testing, used for the determination of material characteristics.Depending on the material, the test is used in accordance with the respective industry standard for determination of the yield strength, tensile strength, strain at break and other material properties.. In the tensile test a material specimen is strained until it .Key Ideas in Tensile Testing. The next section will focus on central concepts associated with tensile testing. Tension and Pressure. These are the fundamentals of the study of materials. Stress is defined as the pressure exerted per unit of area. Strain is the percentage value that represents the ratio of the new length to the original length .

A universal testing machine with a 300 kN hydraulic capacity was used for direct tensile testing. As shown in Fig. 4, a set of customized fixtures, including a clamp, transfer connector, universal hinge and metal frame, was designed for the direct tensile test to avoid secondary flexural stress. Two linear variable displacement transducers .

Resultado da Essa é a sua fonte diária de resultados de jogo do bicho nas maiores e mais importantes bancas do Brasil, assim como resultados da megasena e outras loterias federais. Esse é o lugar certo para você que deseja entender mais sobre essa parte única da cultura brasileira, assim como sua história, .

assessing impact characteristics via tensile test data|weld metal tensile strength test